PurOtecs Data Sheet HYDRO ROLL Flume (PDF)

As a general rule of thumb, Purotecs discourages the use of traditional flumes. Generally, a high organic load carried in recirculated flume water prevents effective sanitation and instead uniformly contaminates product in a flume. The exception to the rule is when a minimal organic load is maintained in the recirculated water. The low organic load allows any sanitizer to burn through the organic load and maintains an effective sanitizer level. When combined with the hydro roll flume’s physical action your product is turned over in the flume water and all surfaces are exposed to the sanitizer.

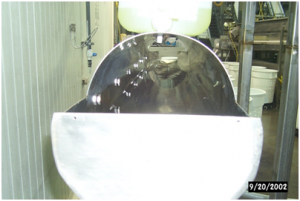

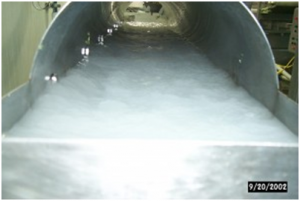

Water enters the hydro roll flume from side nozzles. The nozzle spray action causes the water to roll. The amount of rolling action is controlled by the amount of water entering from the sides. The required treatment times are shorter since you get better product coverage. The Purotecs Hydro Roll Flume TM system is manufactured to fit into your process line. The length, width and water flow determines the treatment time.

Water enters the hydro roll flume from side nozzles. The nozzle spray action causes the water to roll. The amount of rolling action is controlled by the amount of water entering from the sides. The required treatment times are shorter since you get better product coverage. The Purotecs Hydro Roll Flume TM system is manufactured to fit into your process line. The length, width and water flow determines the treatment time.

A Programmable Logic Controller (“PLC”) provides the flume with the desired sanitizer levels. When used with ozone, the ozone is released into the flume from nozzles located along the side of the flume.

Hydro Roll Flume Benefits:

Hydro Roll Flume Benefits:

- Large Bacteria and Mold Reductions

- Integrated Treatment System

- High Ozone Concentrations

- Fits into Existing Systems

- Increased Ozone Contact

- Double Treat with Water and Gas Bubbles